Electrical Energy-related Bibliography

Photovoltaic Cells

Bio-Photovoltaic Cells

Chlorophyll-based Bio-Photovoltaic Cells

Robert Murray-Smith. 2014. Making a Solar Cell from a Leaf. Video. Retrieved from youtube.com/watch?v=w0i_Gf55uiE.

- 0:32–1:46: On its use of Cu and Al strips and an electrolyte-impregnated paper towel, and how it's not a battery despite this arrangement; to demonstrate this, a version with significantly larger electrodes was constructed that sandwiched the electrolyte (in a way that left no part of it exposed to light), and which showed 0uA

- 1:50–: In contrast, the 'solar cell' version / geometry (which had an active area of, perhaps, 20cm2) produces 40–50uA under (ambient) fluorescent lighting, even after three days

- 2:44–3:32: On the lack of corrosion of the electrodes, and the use of disparate metals to provide some 'current direction'. “But we're getting constant supplies of small amounts [of current] from that structure, where we've got leaf extract between two different metals. I used these two different metals to do a bit of current direction. If you have two same metals then you still get an output from it, but the output is much, much lower because, I think, the electrons don't know where to go. And in this setup, they know where to go, so you get a much better capture of it.”

- 3:46–4:33: A rather unconvincing demonstration of its increased output under direct exposure to a halogen light. (Spoilers: it didn't seem to make a difference, at least within the few seconds that the exposures were changed.)

Robert Murray-Smith. 2014. Making a Solar Cell from a Leaf: Extracting Chlorophyll into a Deep Eutectic Solvent. Video. Retrieved from youtube.com/watch?v=rhUnFYNbC_k.

In this video, approx. 10g of birch leaves are placed into 250mL of deionised water and blended for 20 mins; the resulting liquid is double-vacuum filtered. The resulting filtrate will ultimately be added to a deep eutectic solvent made from a 2:1 (molar ratio) mixture of Mono-ethylene(?) glycol and (?) chloride. (The chemical names were not clear from the audio, but the molecular masses were given as 62 and 139g/mol, respectively, suggesting they are, in fact, Ethylene glycol (62.07g/mol and Choline chloride (139.6g/mol).)

To prepare the solvent, the mixture needs to be heated to approx. 80°C (whereupon its consistency will change from that of a more sugary molasses to a liquid). This is then mixed, 1:1 with the chlorophyll extract, and kept at approx. 95°C until its volume has reduced back down to a single unit of volume, by which time virtually all of the water will have evaporated (given the much higher boiling points of the other solvents).

Robert Murray-Smith. 2014. Solar Cell from a Leaf: Update. Video. Retrieved from youtube.com/watch?v=fir5uZpJU74.

In this video, an electrolyte made with twice the starting leaf material is presented, and shown to produce ~75uA (compared to ~40uA from an equally-sized 20cm2 cell); its response upon exposure to a halogen light is also noticeably quicker.

“What that's suggesting to me, and should be suggesting to you, I guess, is that it's the chlorophyll that's actually responsible for the effect that we're seeing.”

Robert Murray-Smith. 2014. Working on the Leaf Based Solar Cell: A Lab Log. Video. Retrieved from youtube.com/watch?v=0E3R1edpQ6U.

The design, as shown at the end of the video, was reported to produce approx. 0.5W/sqm. While still a lot less than the approx. 30 to 50W/sqm that is typically produced by commercial silicon-based PV cells under real-world situations, this is also much better than the 1.2mW/sqm generated by Copper(I) oxide-based cells. And, when the environmental and financial costs of production (and the feasibility of refurbishment) are taken into account, this type of cell becomes even more interesting.

TBC

Robert Murray-Smith. 2014. Solar Cell from a Leaf Update: In The Sun. Video. Retrieved from youtube.com/watch?v=fsEabyztqhY.

Robert Murray-Smith. 2014. Solar Cell from a Leaf: Review and Direction. Video. Retrieved from youtube.com/watch?v=fFRf_p7M1_g.

Cyanobacteria-based Bio-Photovoltaic Cells

The performance of a Bio-photovoltaic system built around the cyanobacteria, Synechocystis sp. PCC 6803, and aluminium-anode over a six-month period is described as averaging approx. 0.2uW/cm2 and 0.37uW/cm2 under dark and light conditions, respectively; scaled up to a 1m2 panel, this could amount to between 2mW and 3.7mW, respectively.

Cambridge University. 2022. Algae-powered computing: scientists create reliable and renewable biological photovoltaic cell. Press Release. Retrieved from cam.ac.uk/research/news/scientists-create-reliable-biological-photovoltaic-cell-using-algae

Bombelli, P et al. “Powering a Microprocessor by Photosynthesis”, Energy & Environmental Science, May 2022. DOI: 10.1039/D2EE00233G

Zinc Sulfide-based

Robert Murray-Smith. 2014. The Birth of a New Type of Solar Cell Video. Retrieved from youtube.com/watch?v=aNGoXjQpU0E.

- 1:54–3:45: Mix Formic acid and Zinc Oxide to produce Zinc Formate (ZnO4-C2H2); recrystallise; dissolve the Zinc Formate in distilled water and add Thiourea (SC(NH2)2) in a 2:1 molar ratio; and recrystallise to recover the Bisthiourea Zinc Formate (BTZF, Zn(HCOO)2-CS(NH2)2)

- 4:09–5:23]: Instead of doing the final recrystallisation in deionised water, add the Lacey Plating Solution ([[https://patents.google.com/patent/US7235165B2/en|US Patent No. US7235165B2, an aqueous solution of oxalic acid, trisodium phosphate and ammonium sulfate) to the mixture instead, which results in a white cloudy liquid. Let the larger Zinc Sulfide (ZnS) crystals settle, and save the resulting clarified liquid, which contains ZnS nanoparticles (whose presence can be verified by shining a laser through the fluid, aka the Tyndall-effect)

- 5:55–6:37: Demonstration of the trace of a green laser appearing bright at first, fading out after a second or so (due to the ZnS nanoparticles being reduced back to Zn+2 ions, which then go back into solution), and reappearing shortly thereafter (due to this ionising process being reversible / an equilibrium process)

- 6:58–10:22: Overview of its relationship to Metal-Insulator-Metal (MIM) diodes, and the latter's (really) high-frequency switching abilities to 'rectify' incoming light (i.e. to treat light as a wave rather than a particle impinging upon the surface of a material)

- 10:22–10:45: On the characterisation of MIM diodes in terms of the work functions of the two metals and the electron affinity and band-gap of the insulator, and the selection of Cu, Al and ZnS in this case

- 10:45–: On how a Cu – Al on insulator – Cu strip cell (with various combinations of fluids between the Al and the insulator) can produce 20–40uA for several hours

Robert Murray-Smith. 2014. Graphene Transparent, Flexible Brand New Solar Cell. Video. Retrieved from youtube.com/watch?v=p5eRLxMHIi0.

In this video, an alternative to the traditional 'flat-plate current collector – thin-layer photo-active material – transparent conductive layer' sandwich is presented. Specifically, strips of disparate metal are mounted at opposing sides of a clear plastic sheet (to function as the collectors, with the use of Cu and Al to provide directionality), and a 95% photo-active material / 5% graphene (1g/L) / nano-fibrous cellulose (5g/L as a binder) is painted on to the plastic; this mixture was subsequently described as 5mL of the ZnS nanoparticle solution added to 100mL of nano-fibrous cellulose suspension (at a concentration of 5g/L) and 100mL of graphene suspension (at a concentration of 1g/L).

When exposed to (ambient) fluorescent lighting, it produced no noticeable current; outdoors in the shade, an approx. 25cm2 cell produced ~5uA, which went up to ~9uA in the direct sun.

Although follow-up questions included how would this perform as a 3D cell (given that the conductors are provided by the graphene, which permeate the paste), given the very small amounts of current produced, one has to wonder if its efficiency can be increased to a usable level.

Robert Murray-Smith. 2014. The Effect of Some Dopants on the New Type of Solar Cell. Video. Retrieved from youtube.com/watch?v=NEo3vP-iFVg.

In this final video in the series, the flexible panel described above is reproduced (this time on paper) and compared with similar cells made with 0.3% dopants of Cu and Mn. Indoors, under (ambient) fluorescent lighting, control produced 0uA. A few square centimetres of activate material doped with Cu produced ~0.2uA, with the Mn-doped cell producing 1.3uA.

Triboelectric Effect

Rain Fuel Generator (2022)

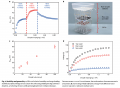

Xu, W. et al. (2020). A Droplet-based Electricity Generator with High Instantaneous Power Density. Nature, 578(7795), 392–396. doi:10.1038/s41586-020-1985-6.

From the abstract, “Extensive efforts have been made to harvest energy from water in the form of raindrops, river and ocean waves, tides and others. However, achieving a high density of electrical power generation is challenging. Traditional hydraulic power generation mainly uses electromagnetic generators that are heavy, bulky, and become inefficient with low water supply.

“An alternative, the water-droplet/solid-based triboelectric nanogenerator, has so far generated peak power densities of less than one watt per square metre, owing to the limitations imposed by interfacial effects — as seen in characterizations of the charge generation and transfer that occur at solid–liquid or liquid–liquid interfaces.

“Here we develop a device to harvest energy from impinging water droplets by using an architecture that comprises a polytetrafluoroethylene (PTFE) film on an indium tin oxide substrate plus an aluminium electrode. We show that spreading of an impinged water droplet on the device bridges the originally disconnected components into a closed-loop electrical system, transforming the conventional interfacial effect into a bulk effect, and so enhancing the instantaneous power density by several orders of magnitude over equivalent devices that are limited by interfacial effects.”

Robert Murray-Smith. 2022. Rain Power: A Major Breakthrough. Video. Retrieved from youtube.com/watch?v=ee3WW0OnBL0

Robert Murray-Smith. 2022. 1459: How To Make A Rain Fuel Generator. Video. Retrieved from youtube.com/watch?v=JWHl4TLM9TY.

In these videos, the basic design of the triboelectric generator described in Xu, W. et al. (2020) is presented. The use of a plastic panel — aluminium substrate — PTFE / plumbers' tape — aluminium electrode, the 'getter' (in place of the glass panel — indium tin oxide substrate — teflon coating – aluminium electrode of the original paper) is also investigated and found to be a viable alternative.

Problems with this approach, which were mentioned in subsequent discussions, included the potential corrosion of the aluminium, the potential difficulty of bonding the teflon tape to the substrate, and the relatively low voltage spikes (on the order of 60mV).

cayrex2. 2022. Rain Fuel Generator from Conductive ink. Video. Retrieved from youtube.com/watch?v=334eNJG3EAI.

Robert Murray-Smith. 2022. 1460: Improving The Rain Fuel Generator. Video. Retrieved from youtube.com/watch?v=Mp8mMu33mNk.

In these videos, the design is further refined to use a plastic panel — aluminium substrate — conductive ink — film of (outdoor) polyurethane varnish — aluminium electrode. The varnish is applied by submerging the assemblage (minus the electrode) into an outdoor varnish and allowing it to 'drip dry', before mounting the electrode on top of the varnish film (which now serves the same purpose as the PTFE tape in addition to protecting the conductive ink from the elements).

Not only is the resulting device easier to construct, a similarly sized harvester generated on the order of 250mV (compared to the 60mV of the teflon tape approach).

Information on how to make the conductive ink used in Murray-Smith (2022) can be found in:

Robert Murray-Smith. 2022. 1381: How To Make A Conductive Ink. Video. Retrieved from youtube.com/watch?v=q32Fr0Hh84o.

Robert Murray-Smith. 2022. 1463: Large Rain Fuel Generator in Parallel: An Exploration. Video. Retrieved from youtube.com/watch?v=jIcK5CBue4M.

In this follow-up video, a simple 'parallel' generator is made using a wide arrangement of PTFE tape and strips of Al tape; results from a more 'dribbly' than showering watering rose were approximately 0.2uA short-circuit current / 110mV. Note sure what this would be like under actual rain-like conditions, though.

Open Questions

- Curiously, in all of the replications, the water was only dropped from a height of a few centimetres (maximum), one drop at a time; even the original study used an an array, then a matrix of droppers. How might the results vary if, e.g., droplets coming from a raised watering can (~1–2m), or actual rain (hundreds to thousands of metres) were used instead? How would this affect the 'harvested' charge?

Moisture-Electric Generation

Robert Murray-Smith. 2022. 1543: Self-charging Battery Generates Electricity from Moisture in the Air. Video. Retrieved from youtube.com/watch?v=kIc2mlcMTMw

Zhu et al. Boosting Moisture-induced Electricity Generation from Graphene Oxide through Engineering Oxygen-based Functional Groups. Nano Energy, Volume 94. 2022. https://doi.org/10.1016/j.nanoen.2022.106942